%20

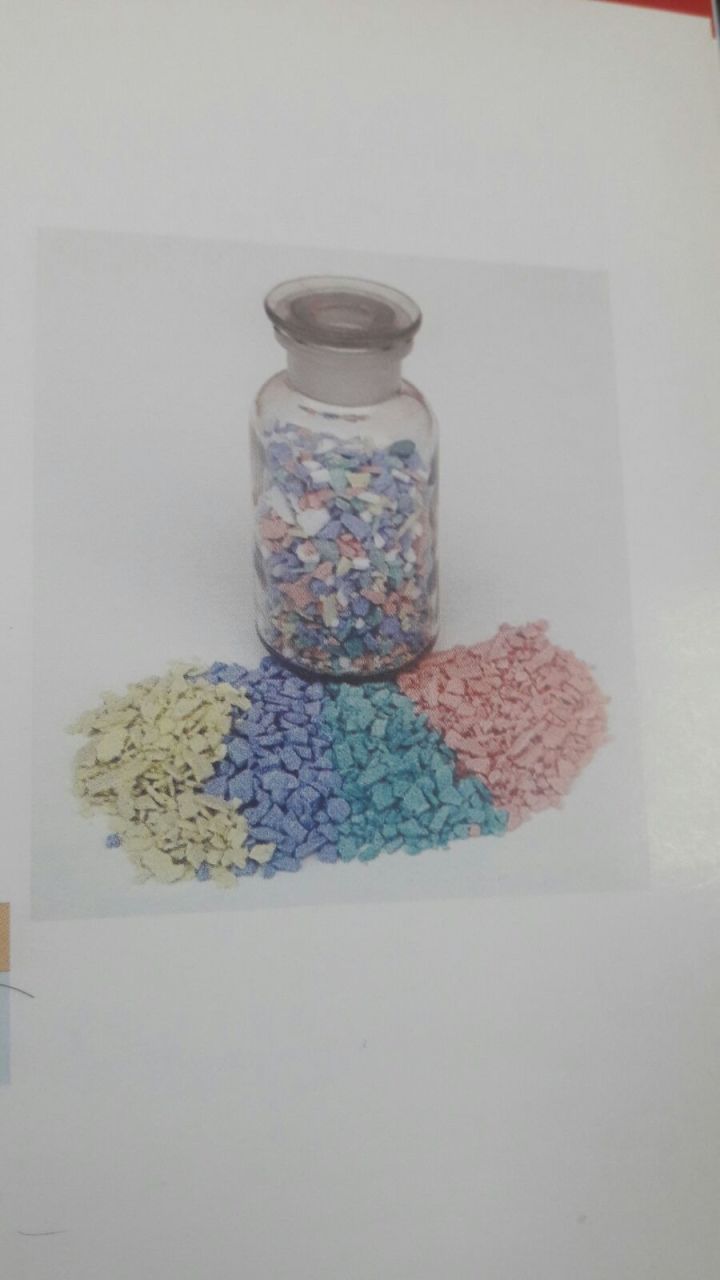

Granular Fluxes for Aluminum Alloys

1-Covering Slag Removal and Cleaning Granular Fluxes

| Name of the product | Purpose of usage | Usage Dosage | Application |

| Clenal G 101 | 99% Pure Bullion and Clean Recycling | 0.125-0.25% | Less than 2% of Mg |

| Clenal G 102 | Pure Bullion, scrap and recycled | 0.125-0.25% | LMO, LM2 etc. and |

| Clenal G 103 | Very Dirty Scrap and Return | 0.125-0.25% | for Aviation Alloys |

2-Sodium Free Granular Flux

| Name of the product | Purpose of usage | Usage Dosage | Application |

| Clenal G 506 | For Aluminum Alloys with more than 2% MG | 0.125-25% | Alloys with high Si content such as piston |

3-Fluorine-Free Fluxes

| Name of the product | Purpose of usage | Usage Dosage | Application |

| Clenal G 106 | Fluorine-free cover, slag removal and cleaning for Al alloys | 0.125-0.25% | See technical data sheet |

4-Sodium and Calcium Free Granular Fluxes

| Name of the product | Purpose of usage | Usage Dosage | Application |

| Clenal G 507 | Na and Ca-free cover and slag removal and cleaning | 0.125-0.25% | See technical data sheet |

5-Magnesium Remover Granule

| Name of the product | Purpose of usage | Usage Dosage | Application |

| Demag G 100 | It is used as a Mg remover in a melt with a high Mg ratio. It oxidizes Mg and separates it from the melt. The other removal method of Mg is with chlorine gas and it can be done where chlorine use is accepted. | 1% for every 0.1% Mg removed | It is used in cases where excessive Mg is undesirable. |

6-Degassing Granular Flux

| Name of the product | Purpose of usage | Usage Dosage | Application |

| Clenal G 109 | As the temperature rises, the increased hydrogen dissolution leads to gas voids as the alloy freezes, flux powder or tablet can be used for this. | 0.15-0.25% | See technical data sheet |

7-Special Flux for High Pressure Casting

| Name of the product | Purpose of usage | Usage Dosage | Application |

| Clenal G 105 | It is a protective cover, slag removal and cleaning flux especially for high pressure casting. | 0.125-0.25% | high pressure casting |

MCC Fluxes for Copper Based Alloys

| Name of the product | Purpose of usage | Usage Dosage | Application |

| Coperal 11 | Fluxes that create an oxidizing environment to prevent hydrogen uptake | 1% of molten copper | It is produced for commercial red metal. |

| Coperal 141 | Fluxes that create an oxidizing environment to prevent hydrogen uptake | 0.5-1.0% | Easy and lead Bronze |

| Coperal 161 | Fluxes that create an oxidizing environment to prevent hydrogen uptake | 1-2% | Red, bronze and nickel bronze melted in crucible or revebater |

| Copflux 80 | To protect copper alloys from oxidation and reduction | 1% in the first stage of melting | For highly conductive coppers |

| Copflux 490 | To protect copper alloys from oxidation and reduction | 1% to bottom of hot pot and top of charge | Brass-solder metal |

| Exinal 30 | Copper alloys containing aluminum | 0.25-1% in more than one step | All copper alloys containing aluminum |

| Gasless 304 | Tablet for removing hydrogen from copper alloys | 1 tablet for every 100 kg of copper | Suitable for all copper and its alloys. |

| Deslag 205 | Slag collector for most copper alloys | 0.3-0.4% in two digits | For all copper alloys |

Be the first to comment on this product!